Toxic cleanup technique can get more rare earth metals out of ores

source link: https://arstechnica.com/science/2022/11/toxic-cleanup-technique-can-get-more-rare-earth-metals-out-of-ores/

Go to the source link to view the article. You can view the picture content, updated content and better typesetting reading experience. If the link is broken, please click the button below to view the snapshot at that time.

Power ups —

Toxic cleanup technique can get more rare earth metals out of ores

As an added bonus, cleanup after rare earth extraction would be much easier.

John Timmer - 11/3/2022, 3:07 PM

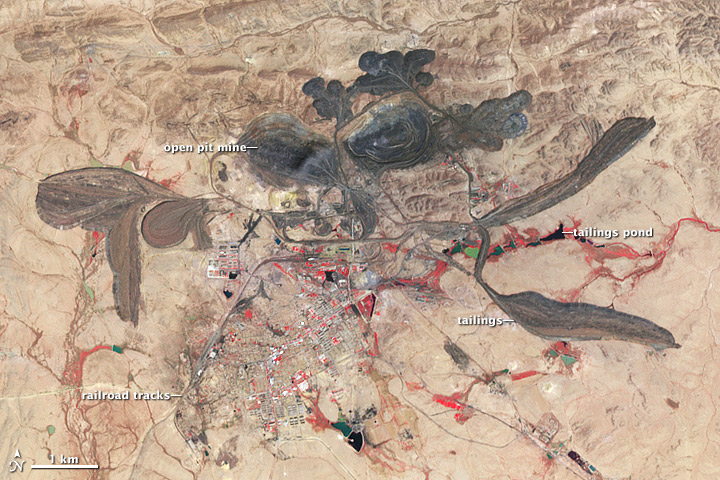

A variety of modern technologies, including permanent magnets that have been used in everything from earbuds to wind turbines, rely on rare earth elements. While the metals aren't actually especially rare, they don't occur at high concentrations in the Earth's crust. As such, extracting them is expensive and tends to produce a lot of environmental damage, meaning that most of the supply comes from a small number of countries (see the chart here), leaving the supply at risk of political fights.

So the potential to get much more out of existing rare earth mines is obviously very appealing. And the method described in a paper released on Monday seems to offer it all: more metal per ore, much lower cost, and far less worry about mining waste.

Less leaching

Many of the best rare earth deposits occur in places where nature has concentrated the elements for us. These tend to be sediments formed from materials where the rare earth elements will react or interact with the sediment, coming out of solution and gradually building up the concentration in the ore. The usual method of extracting the elements from these ores essentially involves reversing that process. An ion-rich solution is pumped through the ore, and these ions displace the rare earths, allowing them to leach out of the ore. Typically, the solution used is ammonium sulfate.

AdvertisementThe production of ammonium sulfate has its own energy and materials costs, and it leaves the material behind in the ore, which may require an environmental cleanup afterward. And the process isn't very selective; lots of other, cheaper metals, like aluminum and calcium, also come out of the ore and need to be separated from the desired products.

The idea behind the new work was to use an electrical current to simplify the process. The standard leaching relies on the flow of an ion-rich solution through the ore to move the rare earth elements out of it. But once that solution displaces these elements from the ore, they return to being ions in a solution. In that state, an electrical current should drive them to the oppositely charged electrode. In theory, this should mean that less of the leaching solution is needed to get material out of the ore, and thus there should be fewer environmental issues afterward.

This sort of electricity-driven purification has been used to decontaminate soils with high levels of metals. But it's not been tried on this sort of mining before. The idea worked even better than the researchers expected.

Recommend

-

8

8

Rare Chunks of Earth's Mantle Found Exposed In Maryland

-

5

5

News and Trends Noam Chomsky Warns China Is Gaining a 'Near Monopoly' Over Rare Earth Metals Noam Chomsky believ...

-

5

5

March 18, 2022

-

6

6

Get WIRED for just $29.99 $10. Subscribe Now...

-

8

8

What Is The Rare Earth Hypothesis? ...

-

6

6

November 8, 2022 ...

-

5

5

Breadcrumb ...

-

4

4

Huge rare earth metals discovery in Arctic SwedenPublished17 hours ago

-

10

10

Small Near-Earth Asteroid Surfaces Have Few Precious Metals, Study Finds Do you develop on GitHub? Yo...

-

5

5

Study finds elevated levels of toxic metals in some mixed-fruit juices and soft drinks Andrew J. Yawn [email protected] 504-247-1443

About Joyk

Aggregate valuable and interesting links.

Joyk means Joy of geeK