After making V8s more efficient, Tula turns its hand to EVs

source link: https://arstechnica.com/cars/2022/08/after-making-v8s-more-efficient-tula-turns-its-hand-to-evs/

Go to the source link to view the article. You can view the picture content, updated content and better typesetting reading experience. If the link is broken, please click the button below to view the snapshot at that time.

a little here, a little there —

After making V8s more efficient, Tula turns its hand to EVs

The company wants to treat EV motors like a beating heart.

Roberto Baldwin - 8/4/2022, 3:02 PM

SAN JOSE, CALIF.—Electric vehicles are all about small gains in efficiency leading to increased range. Reduce the drag, tweak the acceleration curve, and increase the regenerative braking, and you get a few more miles. Car tech company Tula has come up with another solution to enhance efficiency.

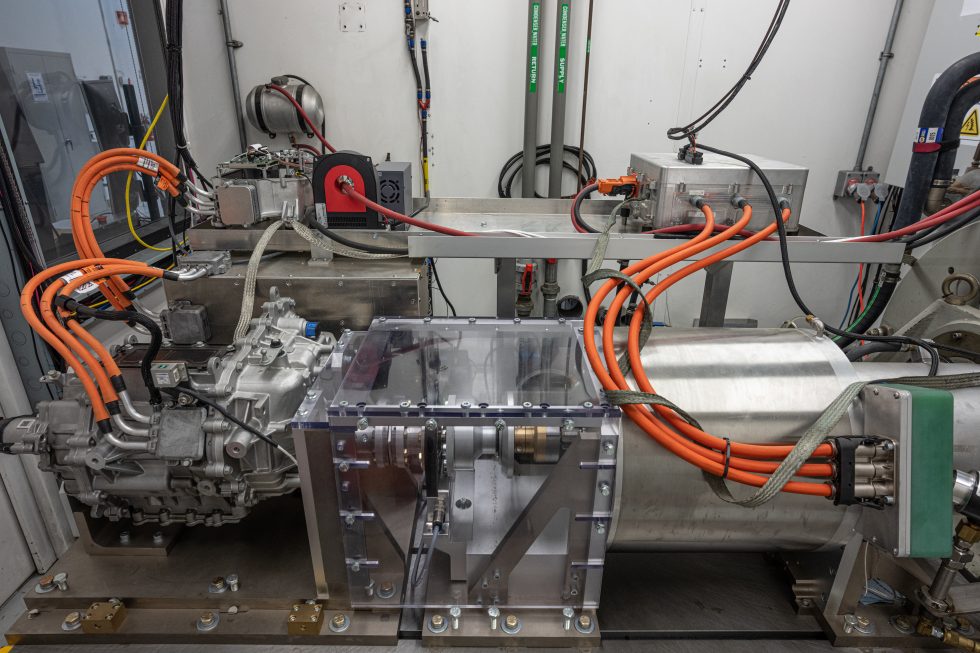

Called Dynamic Motor Drive (DMD), the system pulses the electric motor to operate within a "sweet spot" of efficiency. DMD adds efficiency and removes one of the more controversial materials found in EV motors: rare earth metals. The result is an efficiency gain of about 3 percent. That's not a huge boost, but if your vehicle gets 300 miles of range, for instance, you get nine extra miles of road you can cover. But the system also sets itself up to work in a world with fewer rare earth magnets.

Those rare earth magnets cost automakers a pretty penny, and they're not aligned with the green positioning of EVs. Currently, 90 percent of the EV industry's materials for these magnets (mostly neodymium) come from China. Since late 2021, the price of those materials has increased by about 90 percent. There are plans to increase rare earth mining in the US, but considering the environmental precautions that need to be taken, it still won't be cheap.

Mining and refining neodymium takes a huge toll on the environment. EVs are supposed to be the greener answer to gas-powered vehicles, so it's not a good look when mining the magnets that go into an EV can be responsible for introducing toxic chemicals to waterways.

AdvertisementAt issue is that a majority of EVs on the road are still using these interior permanent magnet (IPM) motors. Currently, BMW and Nissan have in-production vehicles that use electrically excited synchronous motors (EESM) in their vehicles. Others will likely make the switch at some point in the future. During a presentation, Tula's senior vice-president of DMD and engineering, John Fuerst, noted that OEMs are largely working toward EESM for their vehicles.

Yet even with their magnet-free motors, neither BMW nor Nissan has created a DMD-capable vehicle. Tula notes that some minor hardware changes have to happen, but most of the DMD secret sauce is in the software that controls the motor.

The biggest issue is figuring out how to force the motor to pulse within the vehicle's efficiency sweet spot. Each vehicle has a point at which the motor speed and torque are aligned in a way to deliver the best use of energy. As an example, Tula shared a graph showing a point where a vehicle is creating about 75 lb-ft of torque at 3,000 rpm. If the vehicle is traveling at a speed that uses less torque—25 lb-ft, let's say—the DMD system will pulse the motor 20 times per second while making it produce 75 lb-ft of torque.

Rather than a continuous delivery of power, it's a pulsed delivery of power. To make sure that doesn't create a driving experience akin to rolling in a vehicle experiencing a series of tiny earthquakes, Tula has been tweaking the system to reduce that sensation.

Recommend

About Joyk

Aggregate valuable and interesting links.

Joyk means Joy of geeK