DuPont and “DuPont” connectors, and how to crimp them properly

source link: http://www.mattmillman.com/info/crimpconnectors/dupont-and-dupont-connectors/

Go to the source link to view the article. You can view the picture content, updated content and better typesetting reading experience. If the link is broken, please click the button below to view the snapshot at that time.

Introduction

“DuPont connector” is a vernacular term which refers to a number of different types of 0.1″ pitch connector. They feature black plastic housings which retain contacts with fingers built into the housing body. All are very similar in appearance but vary significantly in quality and price.

There are various other names often attached to these, such as “TYU Connector” or “JWT Connector” (drop a comment if you know of another). These are acronyms for some of the many Chinese manufacturers, sometimes physically moulded into the product.

In some cases “DuPont connector” may refer to unrelated connector types which vaguely resemble the original design, however are significantly different in detail. Chinese reproductions of Molex SL / AMPMODU MTE and Molex CGrid III are some examples. On this page I’ll be sticking to the original series, and close look-a-likes.

Contents

Mini-PV – (Amphenol ICC – formerly FCI, formerly DuPont Connector Systems, formerly Berg)

Mini-PV wire-to-board housings, headers and a variety of contact sizes and plating options. From left to right: AWG 18-20, AWG 22-26, AWG 22-26 (Tin), AWG 28-32, AWG 32-36. The white strip on the right is a set of snap-off blanking plugs.

Mini-PV was the first 0.1″ (2.54mm pitch) design of this type likely introduced in the 1950s by Berg Connectors which appears to have spent much of its life as a division of E. I. du Pont de Nemours and Company. Its contact measures 1.25mm square and features an elaborate bi-metallic design with a brass contact body and a beryllium alloy spring. As the heading suggests it has changed hands a few times since then.

The original Mini-PV family is still manufactured today by Amphenol in the USA, but is a fairly premium product which is not marketed for hobbyist use, and is priced accordingly, as one would expect for a product which has been produced by Uncle Sam to same specification for more than 70 years. In subsequent decades its design as been copied and altered by other parties.

I found Amphenol ICC’s website quite difficult to navigate, with catalogues incomplete, publicly available datasheets and documentation at best sporadic, and virtually non-existent for tooling. On this page I have summarised the parts which may be of interest to hobbyists who aren’t on a tight budget.

The Mini-PV family features a dazzling array of different contact types (original catalogue).

The most interesting feature is variable spring tension. I use “Ultra-high” types (48257-000LF) as it is rare that I build anything requiring more than 6-8 positions in one connector, and the higher disconnection force eliminates the need for latching.

In practice these should have been labelled “low”, “medium” and “high” as the “standard” type is not standard at all, it is actually a specialty contact which only makes sense in connectors with large numbers of positions.

Spring tension is rated for 1000 mating cycles.

Example part numbers

Numbers in bold can be changed to order connectors with a different number of positions. Note that some don’t correspond to the number of positions, I’ve added a few examples of these to show how to work out the needed part number.

| Housing 1×1 position (quite expensive for some reason?) | 65039-036LF |

| Housing 2×1 position | 65039-035LF |

| Housing 3×1 position | 65039-034LF |

| Housing 1×3 position polarised | 78211-003LF |

| Housing 2×2 position | 65043-035LF |

| Housing 3×2 position | 65043-034LF |

| Polarising blank plug | 65307-001LF |

| Female contact AWG 22-26 (‘ultra high’ mating force, 15µ Gold) | 48257-000LF |

| Female contact AWG 22-26 (‘high’ mating force, 15µ Gold) | 48254-000LF |

| Female contact AWG 22-26 (‘ultra high’ mating force, Tin) | 47750-000LF |

| Female contact AWG 22-26 (‘high mating’ force, Tin) | 47715-000LF |

| Female contact AWG 28-32 (‘high mating’ force, 15µ Gold) | 48254-000LF |

| 36 pin single row snap off header (15µ Gold) | 77311-818-36LF |

| 36 pin single row snap off header (Tin) | 77311-418-36LF |

| 36 pin single row snap off header – long 10mm mating pins (15µ Gold) | 77311-832-36LF |

| 72 pin dual row snap off header (15µ Gold) | 77313-818-72LF |

| 72 pin dual row snap off header (Tin) | 77313-418-72LF |

| 3 position polarised vertical header (15µ Gold) | 69167-103HLF |

| 3 position polarised right angle header (15µ Gold) | 78208-103HLF |

Cut strip / loose piece

The female contact part numbers I’ve listed are for pre-cut (loose piece) packaging. They are considerably cheaper if purchased as “cut strip” (reel packaging) however note that these are designed to be crimped by a “feed through” applicator, which means that cutting them for use in hand tools is quite time consuming.

Pain in the backside: Mini-PV contacts in cut strip form are connected end to end. Lots cheaper, but lots of work to cut them by hand.

Part numbers are in the catalogue. Note that distributors such as Mouser and Digi-Key only stock a very limited range of these contacts in “cut strip” form.

Wire-to-wire system

Mini-PV wire-to-wire housings and contacts

Mini-PV also features a wire-to-wire family. I’ve not been able to find a catalogue which gives an overview of this family. It uses the same female contact as the wire-to-board system, but introduces a male contact and different housings.

The same housing is used for both male and female contacts, with the housings containing male contacts having a shroud permanently latched to it (and rather difficult to remove once fitted) – sold separately. The shrouds latch into the contact opening, not the tabs on the side, same for the mating connector friction latch, so will also latch onto regular unpolarised housings no problem. They latch onto “DuPont” clone housings too.

I found the quality of these to be quite good, comparable to Molex SL (also featuring a high quality wire-to-wire option). Tolerances are tight, and disconnection force is considerable, especially when loaded with ultra high force spring contacts. The dual row types appear to be unique. I’ve not found any other example of a dual row 2.54mm pitch wire-to-wire connector of this style.

If already invested in this system, these are well worth considering however note that 8 positions is the maximum available, and as is always the case with this family, they’re not cheap.

Example part numbers

Numbers in bold can be changed to order connectors with a different number of positions. They are available in single row 2-4 position configurations, and dual row 4-8 position configurations with part number suffixes ranging from 001LF to 003LF for each type.

| Wire-to-wire housing 2×1 position | 67954-001LF |

| Male connector shroud 2×1 position | 67955-001LF |

| Wire-to-wire housing 2×2 position | 68105-001LF |

| Male connector shroud 2×2 position | 68106-001LF |

| Male contact AWG 22-26 (30µ Gold) | 75967-112LF 75967-312LF |

| Male contact AWG 28-32 (30µ Gold) | 75967-111LF 75967-311LF |

| Male contact AWG 22-26 (Tin) | 75653-002LF |

The two part numbers specified for male contacts relates to the direction they are wound onto the reel, and is irrelevant when purchasing cut strips. Pick what’s cheapest / available.

Crimp tools

If you can afford to use these connectors, you’ll also be able to afford to buy the appropriate tools to crimp them, even if only second hand – they are well worth it. I have confirmed six types:

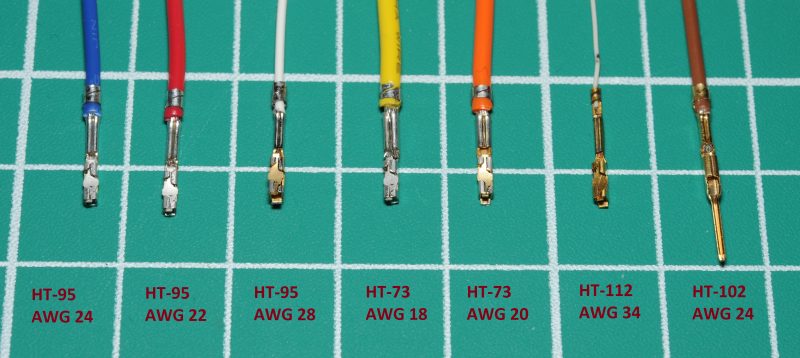

- HT-95 (AWG 22-32): The current and most commonly used Mini-PV tool. It’s large and expensive but crimps these contacts to perfection.

- HT-102 (AWG 22-32): Same as the HT-95 but has a modified locator for male contacts.

- HT-73 (AWG 18-20): For ridiculously large wire sizes.

- HT-112 (AWG 34-36): For tiny wire sizes. Tool and contacts are special order only.

- HT-208A (AWG 22-26): Single die hand tool. Discontinued.

- HT-213A (AWG 28-32): Single die hand tool. Also discontinued.

I’ve not been able to work out what the exact use-case for the HT-73 tool is, given that the wires it crimps are too large to fit into Mini-PV housings. Uninsulated single terminations perhaps?

I’ve not ever been able to find an exhaustive list of all of the DuPont crimp tools and accompanying documentation. Some datasheets are available, but aren’t necessarily much help. There are many other HT-xxx tools in addition to what I’ve listed, all for sale on eBay in various quantities and states of repair. Most of these are for the obscure Maxi-PV family but there are many other types too, likely for obscure, largely forgotten former DuPont connector products.

The price of the most commonly used HT-95 tool brand new seems to fluctuate between high and extremely high. I have seen it sold for as little as $800, as high as $1600.

From left to right: HT-95, HT-102, HT-73, HT-112. Note that HT-95 and HT-112 are identical apart from the locator. All made in the USA.

From left to right: HT-95, HT-102, HT-73, HT-112. These tools have flown under many different brand names and logo variants in the 50 years since their introduction, painting a confusing picture of the history and relationships of the various companies marked on these tools.

Example crimps

HT-73, 95, 102 and 113 examples. Crimps of HT-208A and HT-213A aren’t pictured but are indistinguishable from HT-95.

It is possible to crimp AWG 22-26 contacts in the AWG 28-32 die of the HT-95/102 tools however they will “extrude” (elongate) significantly, potentially beyond the end of the housing insulation once inserted.

Old single die tools

I am uncertain as to why DuPont offered two different series of tools for one connector family. The ergonomics of these tools is vastly superior to HT-95/102, but results are tiny bit rougher. They were discontinued decades ago, and may have been offered as a more affordable alternative the tools I mentioned earlier, however I cannot confirm this as it appears that no pricing information remains in the public domain.

If you do buy one, expect to have to do some repair work on it. I had to re-mount the spring and replace the original locator with a 1×1 housing on both of mine.

Oddball crimp tools

In addition to the tools detailed above, there are a further 4 specialties:

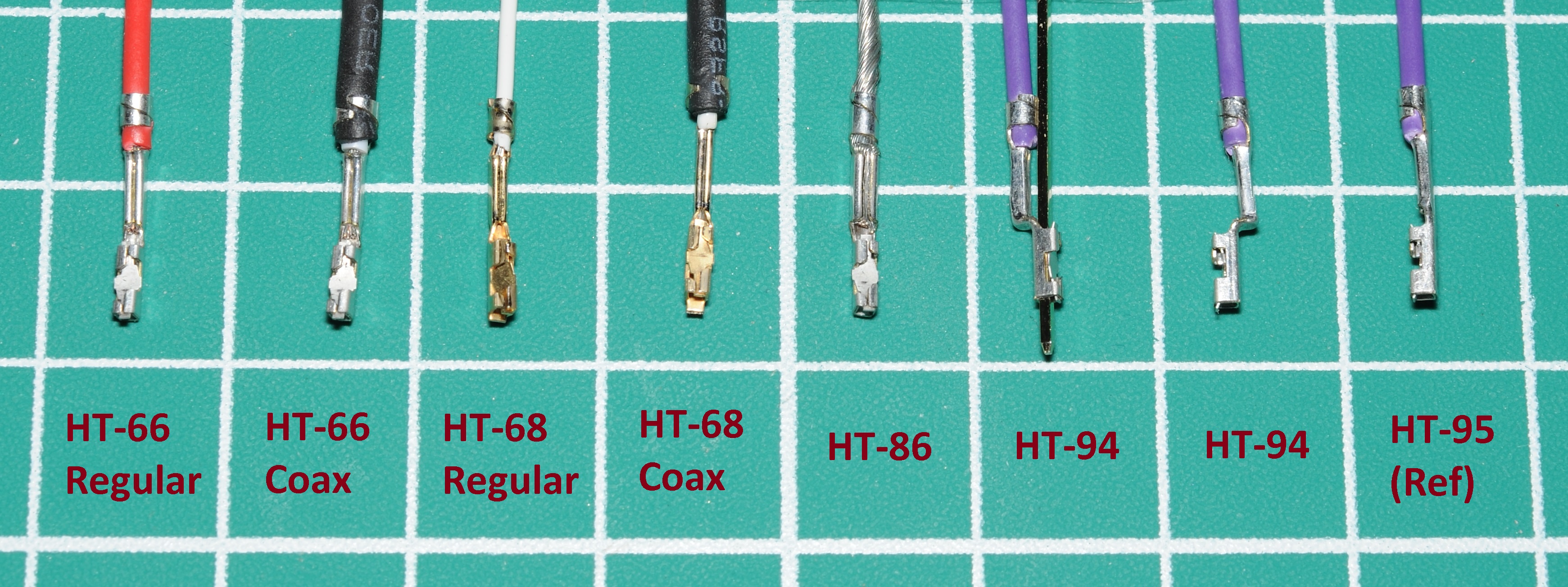

- HT-66 (AWG 22-26): The locator and right hand die in this tool is the same as that of the AWG 22-26 die in the HT-95. In this respect, it is half of an HT-95, and all of an HT-208. The left hand die is also an AWG 22-26 die however features a significantly larger insulation crimper. It is labelled “COAX INSULATION” implying a particularly large diameter insulation. I am uncertain what the use-case of this larger die is, as crimped contacts do not fit into Mini-PV housings.

- HT-68: (AWG 28-32): This is the companion tool of the HT-66 containing two AWG 28-32 dies. The right hand is the same as the AWG 28-32 die of the HT-95 and HT-213. The left hand is labelled “COAX INSULATION” and crimps wire with the same ridiculous insulation size as the HT-66 is intended for. Once again, use-case unknown.

- HT-86: A bare conductor crimper for AWG 18-20 or 22-26 contacts (works best with 22-26). It has quite a large conductor crimper, around AWG 18-20 but a small adjustable insulation crimper, with the intention of crimping the insulation part onto an AWG 18-20 (ish) bare conductor. Crimping the shield of a coaxial cable into a contact is a likely use-case.

- HT-94 (AWG 22-32): This is the most peculiar crimp tool of the lot. It contains exactly the same dies as the HT-95 but a very different locator which bends an offset into the contact while crimping, allowing crimped contacts to be stacked on top of one another. I am uncertain as to how these would be used in practice as the distortion of the contact means they don’t fit into Mini-PV housings.

Oddities pictured. From left to right: HT-66, HT-68, HT-86 and HT-94

From left to right: HT-66, HT-68, HT-86 and HT-94

Example crimps

As mentioned earlier, tools HT-66 and HT-68 can perform regular crimps in their ‘A’ dies. HT-95 is shown for reference, to illustrate the offset performed by the HT-94.

Other crimp tools

- HT-110 (AWG 18-20): For male contacts in this size range. As with all these large sized crimps, they wouldn’t fit into standard housings, so I’m unsure of its use-case. It’s too large for clone contacts, and the original types it’s designed for aren’t stocked by any distributors. Would make a good doorstop if you can pick it up for a couple of bucks.

- HT-114: A very basic low cost scissor action tool. It appears to be quite uncommon.

- SP1552 (AWG 22-24?): Appears to be a well designed counterfeit tool from the early 2000s. Often seen cheaply on eBay. Insulation crimp is a suspect oval shape (it should be circular) and conductor crimp is looser than HT-xx tools. For the money, worth looking at nonetheless.

Crimping with unofficial tools

AWG 24 crimps using 48257-000LF contacts. AWG 28 crimps using 48254-000LF contacts.

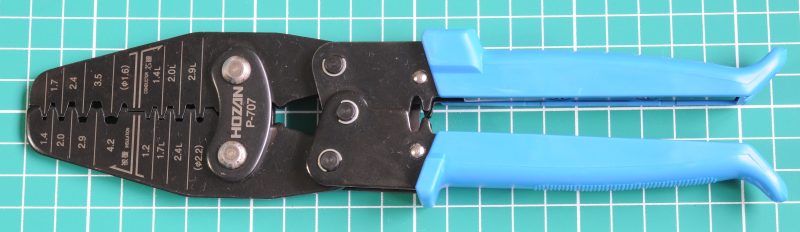

The Hozan P-707 crimps these to near perfection, although it takes three actions to get the job done. It’s quite possible that an HT-95 tool may be able to be obtained second hand for similar or less money.

Any other tools which crimps “M20” clone types will also handle these to varying degrees. The IWISS SN-025 does fairly well however is a little light on the conductor crimp.

M20 – “DuPont” clone (Harwin, and many others)

“DuPont” clone connectors from various manufacturers including Harwin

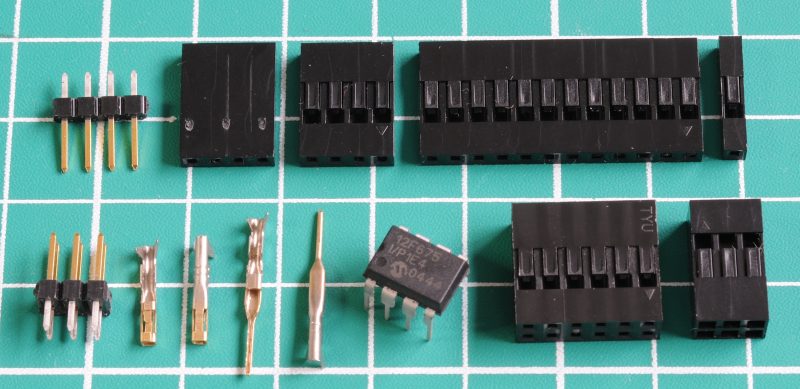

“DuPont connector” generally refers to these. Its contacts are typically bent from a single piece of stamped brass into a box shape around 1.6mm square. Unlike Mini-PV which has 4 different contact sizes, and 3 different spring tensions this type has just one single size, and one spring tension (loose) – covering AWG 22-28 wire sizes, and is available in either Tin or “gold flash” plating (a few atoms thick).

This connector family has a significantly smaller range of components than the Mini-PV family that inspired it, with product being limited to unpolarised housings, pin headers and female contacts. The picture above is basically the lot. Male contacts are available, but are not an official offering from established manufacturers or orderable from well-known suppliers.

There are some examples of unconventional “DuPont” type connector products, for instance 3 position types are commonly found in various polarised varieties for RC servo use, they’re similar to the Mini-PV wire-to-wire type. Toby Electronics (UK) also sell a range of polarised receptacles under their own brand name, once again similar to the Mini-PV type polarised connectors.

I first saw these copycat connectors in the late 1990s. I’ve not yet seen any equipment from prior years containing them.

Harwin are the only well known connector manufacturer producing this type I’ve ever been able to identify. Could they be the creator of the first “DuPont” clones? Today these connectors are made in countless factories in mainland China, comprising the bulk of what is for sale online, many of which are particularly poor quality.

Regardless of where they are made, and by whom, all non Mini-PV types are largely identical to Harwin’s “M20” design, with variation limited to quality of materials, and accuracy of stamping, bending, moulding and plating. As such there is no purpose in listing individual manufacturers of this type.

I used these a lot a decade and more ago however now I only use them for prototypes. Even with the best quality Harwin contacts, spring tension is poor, less than the lowest tension Mini-PV type, and with brass not being a particularly “springy” material, are only good for a handful of mating cycles before they may need to be re-tensioned.

For connections which are frequently mated/unmated and need to be dependable, the money saved isn’t worth the extra hassle created by the poor contact durability (in my opinion), also considering that genuine Mini-PV connectors are reasonably priced when purchased in bulk.

Example part numbers (Harwin):

Numbers in bold can be changed to order connectors with a different number of positions.

| Housing 1×1 position | M20-1060100 |

| Housing 2×1 position | M20-1060200 |

| Housing 3×1 position | M20-1060300 |

| Housing 2×2 position | M20-1070200 |

| Housing 3×2 position | M20-1070300 |

| Polarising blank plug | M20-003 |

| Female contact (Gold flash) | M20-1180042 |

| Female contact (Tin) | M20-1180046 |

| 36 pin single row snap off header (Gold flash) | M20-9993645 |

| 36 pin single row snap off header (Tin) | M20-9993646 |

| 36 pin single row snap off header, right angle (Gold flash) | M20-9963645 |

| 36 pin single row snap off header, right angle (Tin) | M20-9963646 |

| 72 pin dual row snap off header (Gold flash) | M20-9983645 |

| 72 pin dual row snap off header (Tin) | M20-9983646 |

| 72 pin dual row snap off header, right angle (Gold flash) | M20-9953645 |

| 72 pin dual row snap off header, right angle (Tin) | M20-9953646 |

The male contact pictured above is not manufactured by Harwin. Mine were purchased from a Chinese seller on eBay.

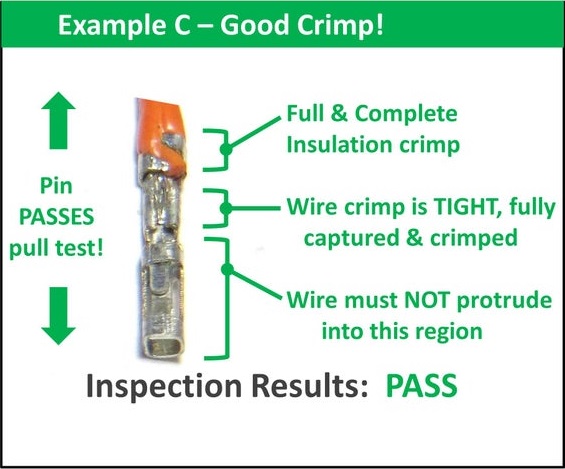

Popular crimping techniques

The majority of all hand crimping of these contacts by hobbyists is done by an SN-28B or similar tool. If you’re happy with a crimp like the one depicted above – my experimentation found you can save yourself $20 by using a hammer.

M20/Clone style contacts crimped with a variety of tools discussed below. See HT-66/68/86/95 descriptions earlier on page.

Official tooling

Factory crimping of this type is done mostly by Chinese designed applicators fitted with dies which produce “reasonable” results (not quite correct, but fairly close).

In the years since I first published this page, I’ve only been able to identify one hand tool which is specifically designed for these contacts and crimps to spec (thanks to a tip from a reader). The Mini-PV hand tools crimp these contacts very well however aren’t designed for them, and need to be specifically adjusted to do so.

Harwin Z20-320. Crimps “DuPont” clone types effortlessly and perfectly. It’s made by Pressmaster in Sweden. At $460 new, it’s not cheap, but a lot cheaper than the DuPont designed tool. It is very rare to find it second hand on eBay. I waited 2 years for the above sample to come up for sale, and the seller wasn’t prepared to give it up for a song.

The Z20-320 has one of the nicest locator designs I have ever seen. Simply place the contact on the sliding gate (from the rear is easiest), then half close the tool. The contact is now held firmly in place to allow insertion of the wire, the bonus being that the gate also stops the wire from being inserted too far. Then simply close the rest of the way to perform the final crimp.

When the Z20-320 is combined with a pre-set length wire stripper i.e. Knipex 121202 the result is a very fast, easy and consistent termination process.

There was an earlier Harwin branded M20 crimp tool tool marked “Z1015-00”, from a different manufacturer (Wezag) – an even less likely item to find for sale.

Using Mini-PV tools with clone contacts

Historic readers of my site may have observed that I spent quite a few years plugging the use of Berg/DuPont (now Amphenol) tools for crimping clone type contacts. I potentially may have doubled, even tripled the second hand price of these tools by doing so. Today I have pulled back from this recommendation a little.

The main problem with using these tools is that clone contacts are quite loose and don’t sit in the locator very well. As a result of this it’s very easy to have a contact swing to one side during crimping. If the jaw is closed with a misaligned contact the anvil will snap off, at which point the tool is finished. It is possible to replace them however the cost (~$100) of a single anvil is typically higher than the second hand price of an entire tool.

Despite that, tools HT-66, HT-68, HT-95, HT-102, HT-208 and HT-213 are respectable for crimping clone contacts, and if you have already invested in one, you made a good choice, so long as you don’t break it. The others I have mentioned require genuine contacts and are of no use here.

For tools HT-66, HT-68, HT-95 and HT-102 – the locator needs to slide back a little further. This can be achieved by either removing the rubber O-Rings pictured, or loosening the hex grub screws retaining the locator pins. Failing to do so will potentially crush the mating end of the contact.

If you are making this modification, tape the O-Rings to the inside of the handle, as you, or whoever owns it next may want to revert it back to its original configuration. Removing the O-Rings is not a preferable method as you are likely to damage them in the process.

For tools HT-208 and HT-213, it’s more difficult. A 1×1 clone housing must be cut down to fit into the space occupied by the original locator, then the fixing plate must be packed up a little. I used a cut out piece of soft drink bottle to achieve this. The added bonus is that in this case you’ll end up with a tool that crimps either gender of contact, and using this arrangement it is not possible for the contact to misalign during crimping.

I wouldn’t recommend HT-68 and HT-213 or the AWG 28-32 die of the HT-95/102 for clone contacts as much as they crimp down to a very small size, resulting in extrusion (elongating) of the crimped termination. This is not an issue with genuine parts as a smaller size is used.

HT-86 does work with clone contacts however it’s quite tight to fit them into the locator.

Crimping (properly) with unofficial tools

M20/”DuPont” clones are one of the few light contact family I’ve encountered which generic tools such as SN-28B and PA-09 suck at crimping.

The problem is apparent when we examine the upper half of the crimp jaw. The original tool is clearly cylindrical, whereas the generic is split, with the intention of curling each side around and back down into the wire again, which is most certainly not what we want for this type of contact.

The Hozan P-707 is an example of a tool which has cylindrical insulation crimpers. It’s been around quite a while and to date still gets the best results for the money, but at $70-80 it’s a little too expensive for most.

Hozan P-707

There are (as of 2020) a couple of lower cost tools which have dies like this:

Recently marketed tools with cylindrical dies

Above is the IWISS SN-025 which is sold as being for “DuPont” contacts . I’m not entirely sure it is. More about it here.

Below is an example of a cheap tool specifically designed for these contacts (and some others). Read more about it here.

Is it possible to mix Mini-PV and M20 style contacts and housings?

In short, no. Despite looking almost identical to common “DuPont” clones, Mini-PV contacts/housings and clone contacts/housings are surprisingly not interchangeable.

It’s barely visible, but you can make out the differences in the image above. The Mini-PV housing has just a tad less room for the contact, meaning that “DuPont” clones don’t fit. Inserting genuine contacts into clone housings doesn’t work too well either – they’re too loose, don’t latch and easily fall out.

This is a massive pain the wallet in the case of the single position housing – the one you’d want for making high quality jump leads. It’s ludicrously priced at $1.38/ea and 85c/ea in quantities of 100 (Mouser). If unprepared to stomach the cost of single position housings, insulating jump leads with heat-shrink is a cheaper option.

Berg/DuPont “Maxi-PV”

There couldn’t be a “Mini-PV” without there also being a “Maxi-PV” connector family, one that did indeed exist. They are stated to be a 0.125″ (3.18mm) pitch design and are the most obscure connector family I’m aware of.

There are no photographs of them in the public domain (that I could find), nor are there any available to purchase, however there are many Maxi-PV crimp tools for sale on eBay (HT-47/HT-48/HT-49). Clearly they were/are used by somebody, for something or other.

Depiction of Maxi-PV connectors from FCI drawing 65410

The above drawing is the only clue I could find as to their appearance. Apparently a “Jumbo”, perfectly scaled up version of the Mini-PV connector. Ever seen one? Got one? Drop a comment!

Recommend

About Joyk

Aggregate valuable and interesting links.

Joyk means Joy of geeK